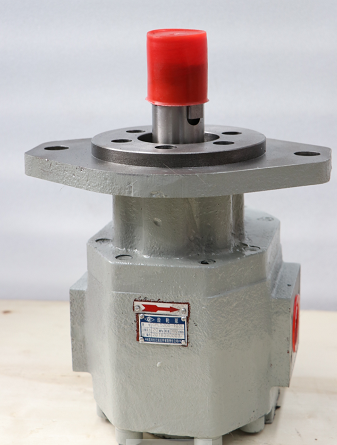

Hydraulic gear pump fault repair, bring you up knowledge

Release date:2018-09-29 作者: Click:

With the increase of use time, the hydraulic systemGear pumpThere will be failures such as insufficient pump oil or even no pumping oil. The main reason is that the relevant parts are excessively worn.The wear parts of the gear pump mainly include the driving shaft and bushing, the center hole of the driven gear and the shaft pin, the inner cavity of the pump casing and the gear, the end face of the gear and the pump cover, etc.When the main technical indicators of the lubricating oil pump fail to meet the requirements after wear, it should be disassembled and disassembled to find out the location and degree of wear and take corresponding measures to repair it.WithGear pump manufacturersCome take a look!

XNUMX. Repair of driving shaft and bushing after wear

After the gear pump drive shaft and the bush are worn, the matching clearance increases, which will inevitably affect the pump oil volume.In case of this, the method of repairing the driving shaft or bushing can be used to restore its normal fit clearance.If the drive shaft is slightly worn, just press out the old bush and replace it with a standard size bush, and the fitting clearance can be restored to the allowable range.If the drive shaft and the bushing are severely worn and the fit clearance exceeds the standard, not only should the bushing be replaced, but the drive shaft should also be increased in diameter by chrome plating or vibration surfacing, and then ground to a standard size to restore the bushing Requirements for cooperation.

508. Repair of lubricating oil pump shell. Repair of shell cracks: shell cracks can be repaired by welding with cast 0 nickel-copper electrodes.The welding seam must be close and porous, and the flatness error of the joint surface with the pump cover shall not be greater than 05 mm.

Repair of the wear of the drive shaft bushing hole and the driven shaft hole: After the drive shaft bushing hole is worn, the reaming method can be used to eliminate the wear marks, and then a bushing enlarged to the corresponding size can be used.The wear of the driven shaft hole is also eliminated by reaming, and then the driven shaft is prepared according to the actual size of the reamed hole;

Repair of the inner cavity of the pump casing: After the inner cavity of the pump casing is worn out, the inner cavity inserting method is generally used to repair, that is, the inner cavity is enlarged and then fitted with cast iron or steel bushings.After inserting the sleeve, line the inner cavity to the required size, and grind off the bushing that protrudes from the end surface to make it flush with the joint surface of the pump casing.

Repair of valve seat: There are two types of pressure limiting valves: spherical valve and plunger valve.After the spherical valve seat is worn, a steel ball can be placed on the valve seat, and then the steel ball can be tapped lightly with a metal rod until the ball valve and the valve seat are tightly sealed.If the valve seat is severely worn, it can be reamed to remove the wear marks, and then use the upper method to make it tight.After the plunger valve seat is worn, a little valve sand can be put in for grinding until it is tightly sealed.

XNUMX. Repair of the pump cover

Repair of the working plane: If the working plane of the pump cover is less worn, manual grinding can be used to eliminate the wear marks, that is, put a little valve sand on the platform or thick glass plate, and then place the pump cover on it for grinding until the wear marks are eliminated. The working surface is flat.When the wear depth of the working plane of the pump cover exceeds 0.1 mm, it should be repaired by turning first and then grinding.

Repair of the drive shaft bushing hole: the repair of the drive shaft bushing hole wear on the pump cover is the same as the repair method of the housing drive shaft bushing hole wear.

Fourth, the flip use of gears

The wear of the gear pump gear is mainly in the thick part of the tooth, and the wear of the gear end face and the tooth top is relatively light.The gears are worn on one side at the tooth thickness, so the gear can be turned 180 degrees and used.When the gear end surface is worn, the end surface can be ground flat, and the joint surface of the lubricating oil pump casing can be ground at the same time to ensure that the gap between the gear end surface and the pump cover is within the standard range.

The URL of this article: http://www.sccjyy.cn/news/374.html

Key words:Hydraulic gear pump,High pressure gear pump,Gear pump manufacturers

Recently Viewed:

- A "Blue Book" was delivered to the door, tax companies gathered together to talk about party building and epidemic prevention work

- Reasons for the motor heating during the use of the gear pump

- What should I do if the piston rod in the hydraulic cylinder leaks out?

- The company organizes personnel to participate in fire safety training

- Changjiang Hydraulics participated in the video training of safety production list management work

- The requirements for hydraulic oil in the hydraulic system must be understood

- How should the multi-way valve of a compressed garbage truck be repaired?

- Technical analysis of gear pump and plunger pump in mechanical engineering

- Changjiang Hydraulic participated in the XNUMXth West Expo

Related Products:

related news:

- In which industries are hydraulic cylinders commonly used

- What is the difference between a gear pump and a screw pump?

- How to maintain the gear pump to make its life longer?

- What are the sealing methods for Luzhou hydraulic gear pumps?

- Causes of noise in gear pumps

- What are the precautions for using gear pumps?

- Reasons for the motor heating during the use of the gear pump

- Measures to reduce vibration and noise of gear pump

- Analysis of Causes of Common Gear Pump Bearing Failures

- The gear pump output flow is not enough, the solution to the pressure can not go up